On the surface, we can determine the homogeneity of the coating, the size, and morphology of the particles, and their chemical composition (coating and pigment particles).

The cross-section can determine the thickness of the paper and coated layers on both sides, particle size, morphology, and their chemical composition in the paper filler as well as in all coating layers. Both phase fillers and pigments can be identified by phase contrast and quantitative chemical analysis. We determine the elemental distribution along the cross-section.

We can also trace all defects in connection with the application of coatings (homogeneity of layers, homogeneity of pigment distribution, possible variations in thickness, cracks, open and closed porosity, poor contact with paper….)

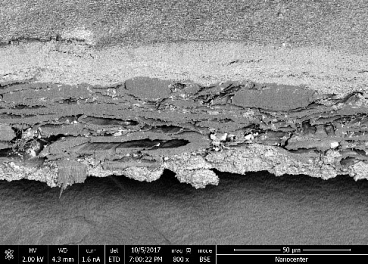

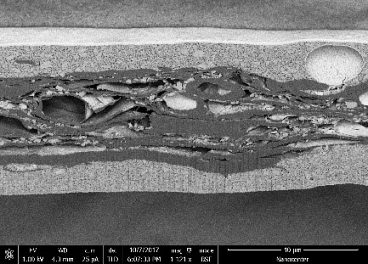

Mechanical preparation of paper cross-sections is usually inappropriate (Picture 01) because it changes the intrinsic state of the paper (damages the edge of the coating, smears the coating or filler particles along the cross-section, and usually splits the fibers). In Nanocenter, with the help of focused ions of the electron microscope, we create a clean cross-section without mechanical damage (Picture 02).

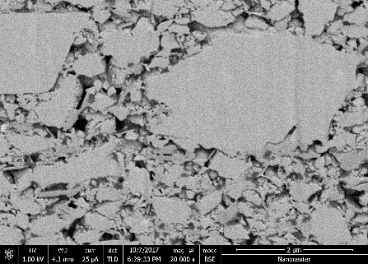

A pictorial and morphological analysis of the paper cross-section in Pictures 02 and 03. Cellulose fibers and filler particles (CaCO3-calcium carbonate) are clearly visible in the paper, while Ca / Mg aluminosilicate particles, kaolin particles, and TiO2 particles are clearly visible in the coating.

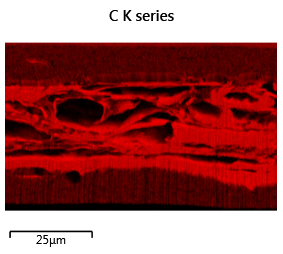

An example of a chemical analysis of the distribution of elements across a cross-section is in Picture 04: the distribution map of individual elements (EDS mapping analysis).